MULTI-NODAL COLUMNAR BRANCHING

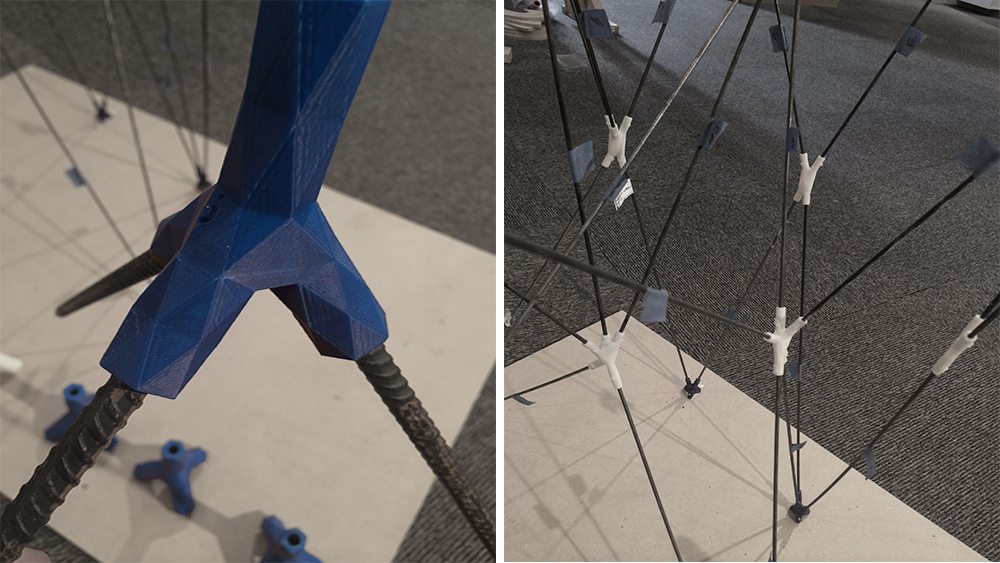

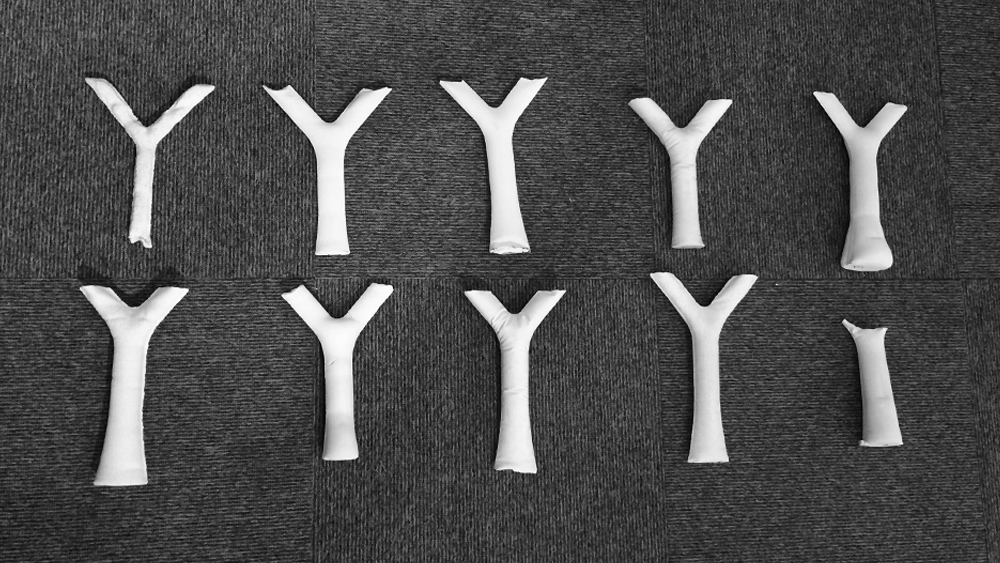

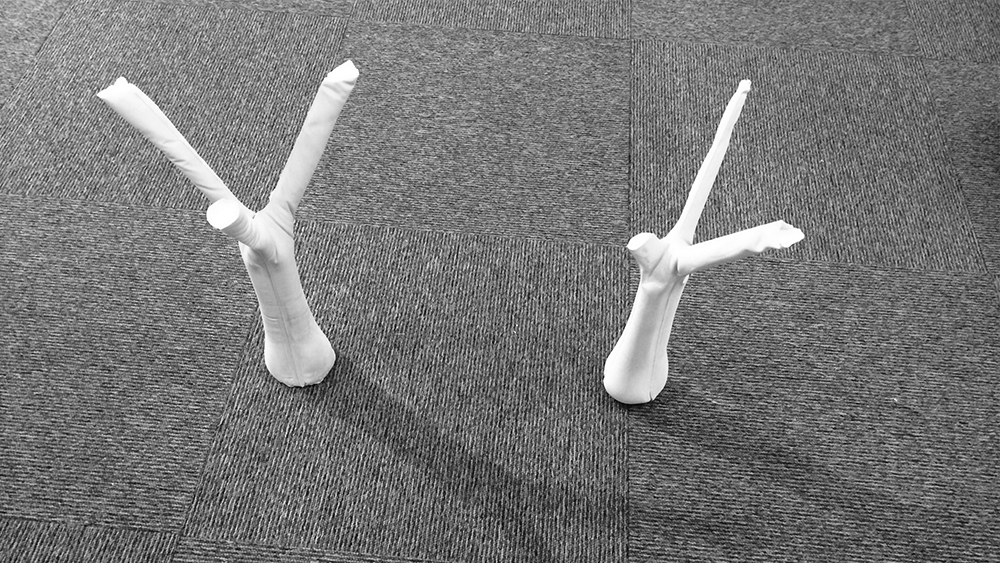

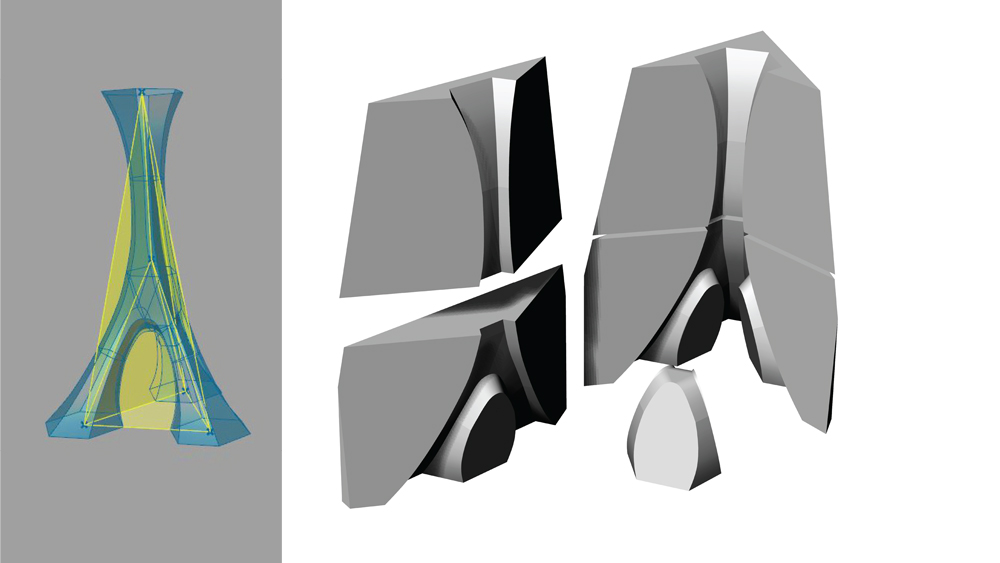

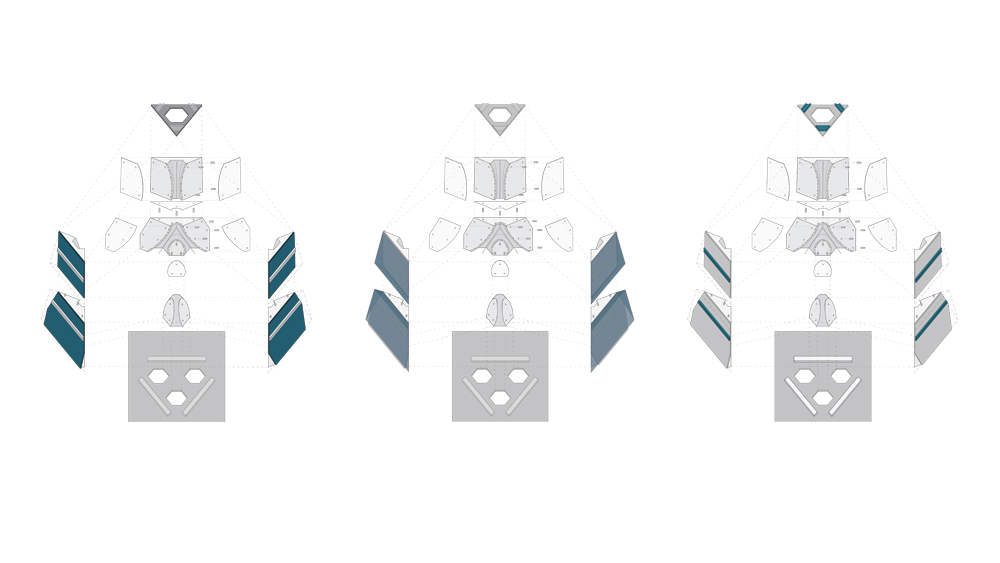

Phase I of multi-nodal columnar branching structural formwork attempted to solve issues related to non-Euclidian branching forms, structural columnar configurations, and simplification of the formwork assembly process by introducing fabric as the primary non-rigid material used in constructing the mold. Much of the determining factor in this research is determined by a syntheses of economic factors relative to formal complexity. By refining the use of ‘bulge wall’ casting process, a series of rigid forms are pressed around the fabric to give shape and direction to the fabric where it is to be filled. Once the pour is initiated the fabric expands and the area bulges around the structural reinforcement and finds an equilibrium to the restrictive wooden forms and the elasticity of the fabric. Perhaps the most significant discovery in the first phase of the research was the introduction of the 3D printed nodes connecting straight runs of rebar/structural reinforcement. This strategy allowed for a very efficient means by which to shape the internal structural system and by-pass the need for custom curvature of the line work of structure.

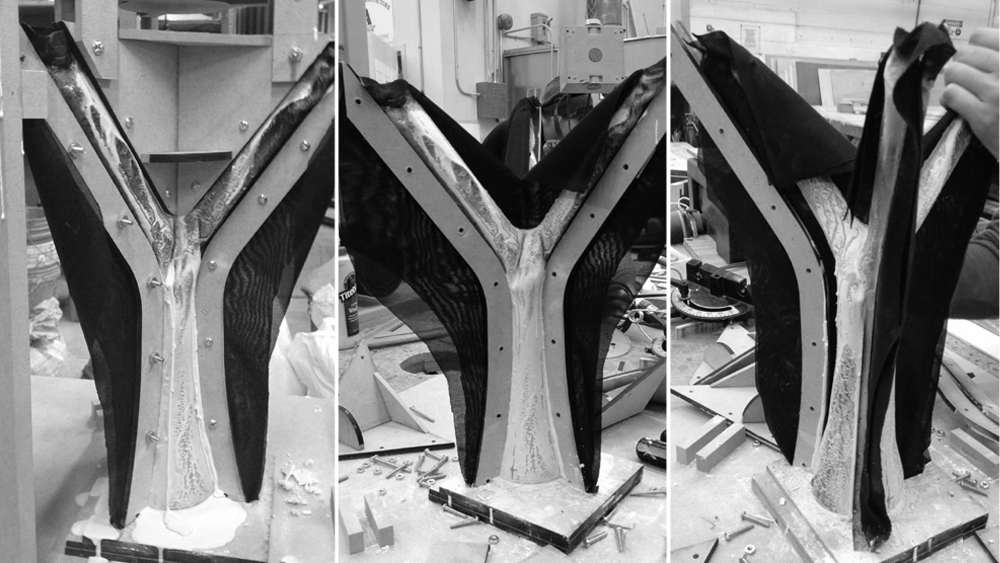

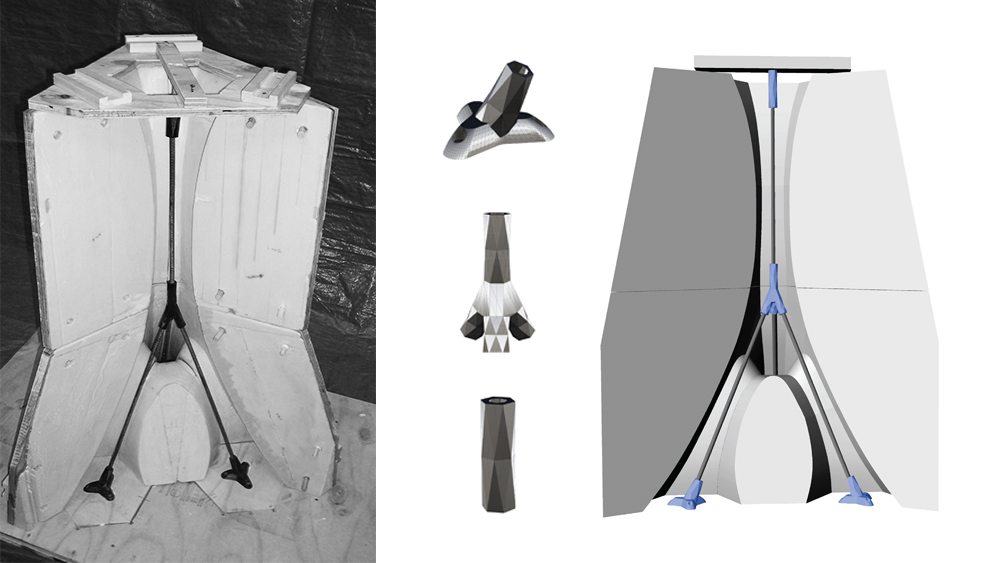

The Phase I formwork strategy encountered challenges when casting the final structure due to inability to precisely control the location of the rebar, and the inconsistency of the cross-section of the member which lead to stress fracture points in the column. Used as a starting point, this provided insight into issues to consider for Phase II of the research. Phase II explored the use of a rigid formwork in milled foam that could be repetitively assembled and disassembled to make use of the multi-cast potential of a short run series of parts. However, the mold, while proving more durable, stable in performance, and geometrically more deterministic, is ultimately only able to be assembled for non-Euclidean geometry through a series of parts and not by one large singular mold. Sequencing of the mold assembly, the integration of the same internal multi-nodal rebar/3D printed structural system, and sealing the formwork were the challenges and test run in Phase II of this research.

Team Members

Halima Arevalo

Renee French

David Garcia

Cameron Martin

Miriela Rico

AnnRuth Warwinu

Industry Partners

CELB @ UT Arlington

Reynolds Advanced Materials

Joshua Hallett

News & Publications

Limb

Related Projects

Cast Columnar Branching I

Non-Euclidean Casting Geometries II

Files

Multi-Nodal Columnar Branching PDF