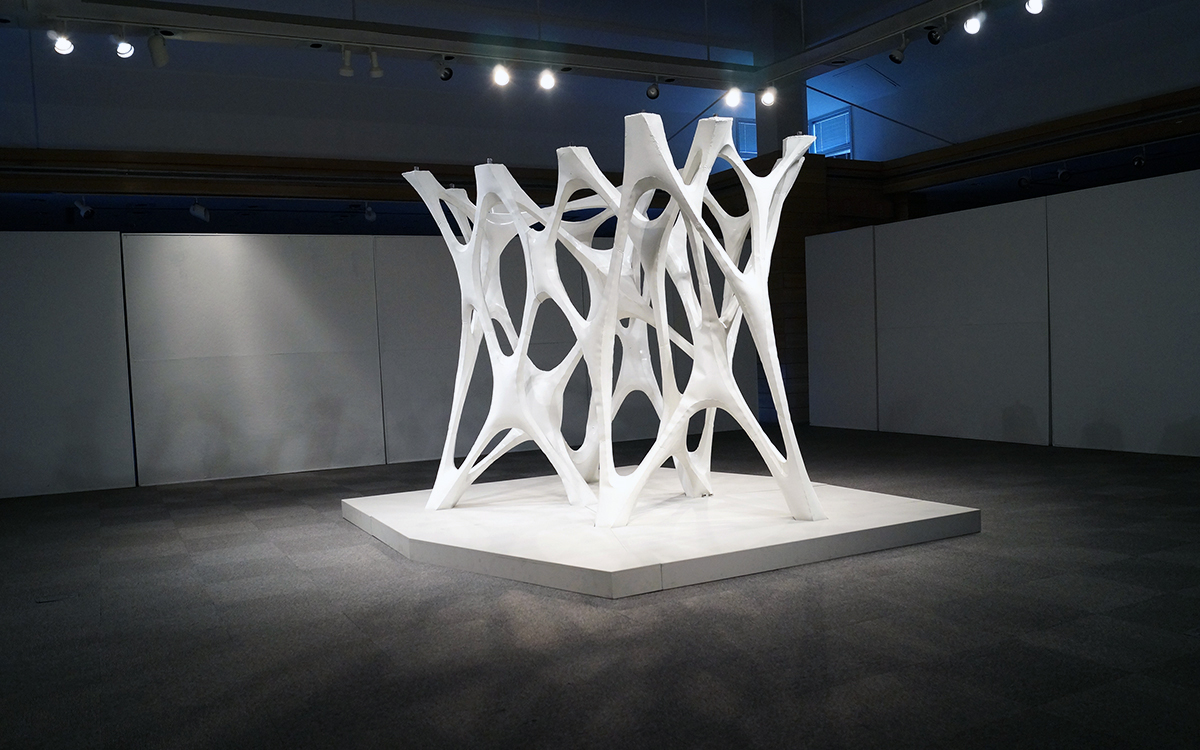

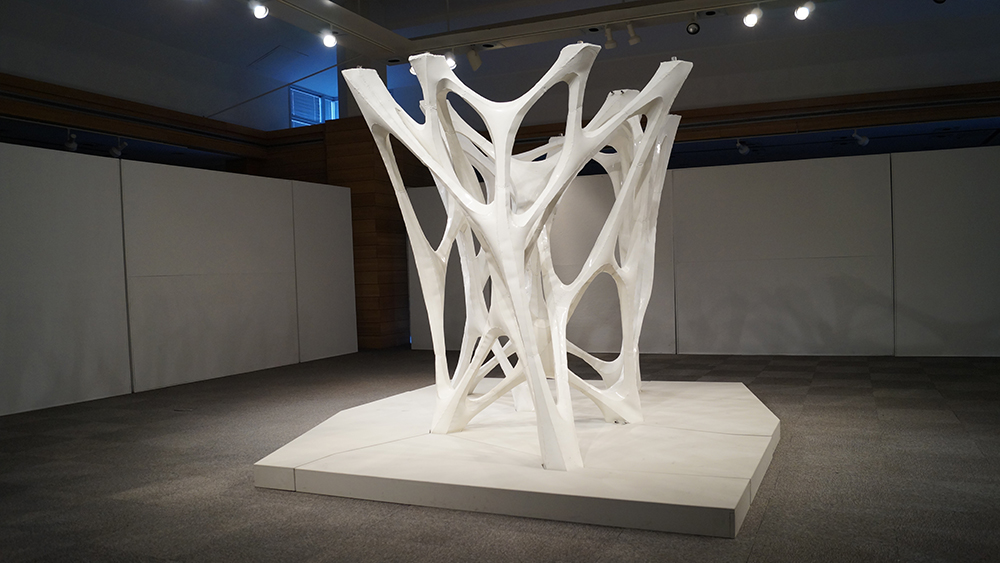

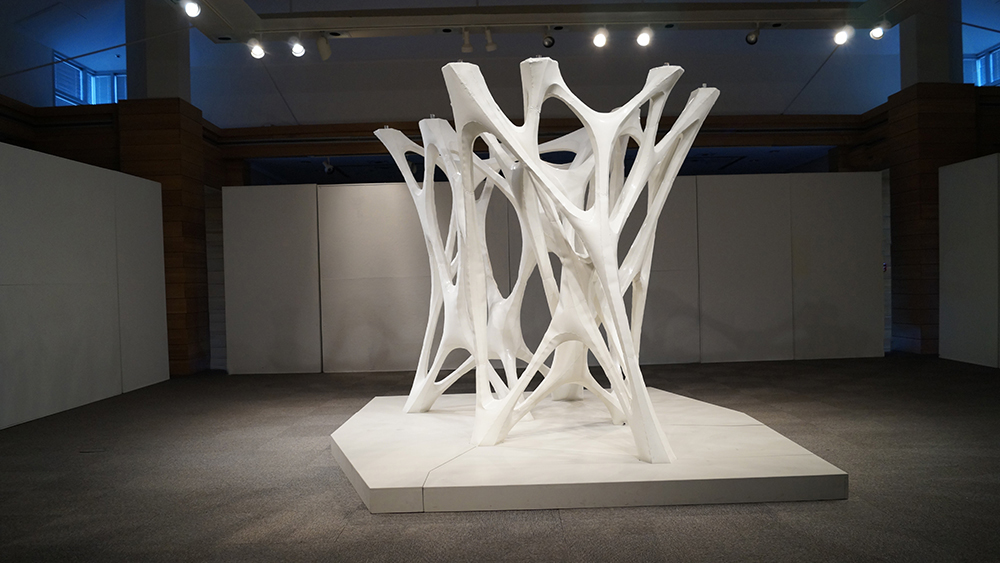

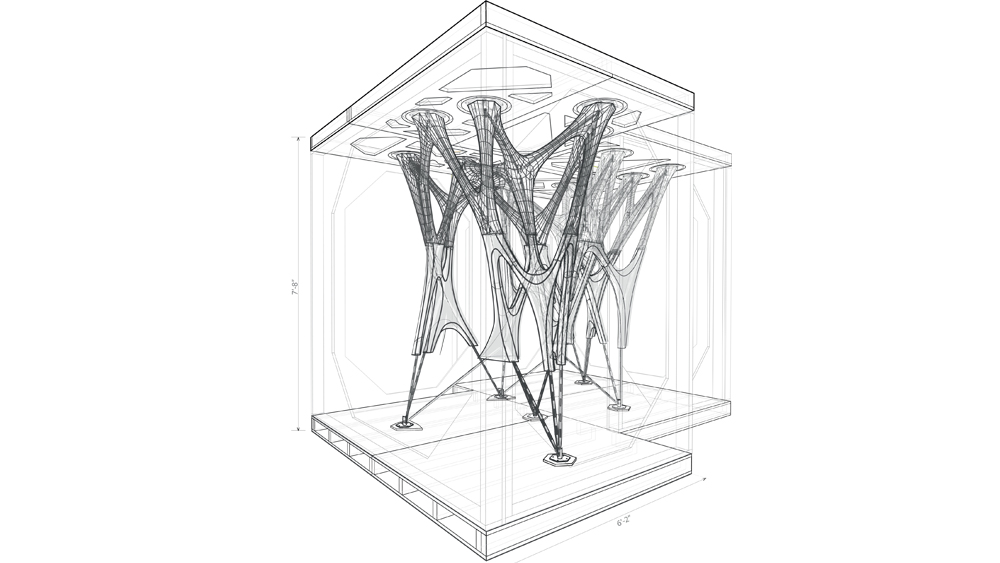

CAST COLUMNAR BRANCHING I

Cast Thicket

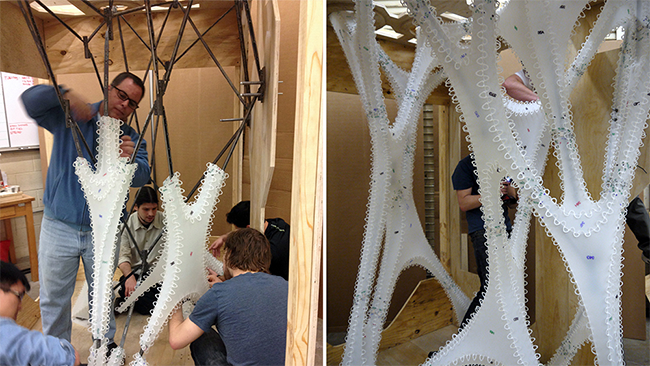

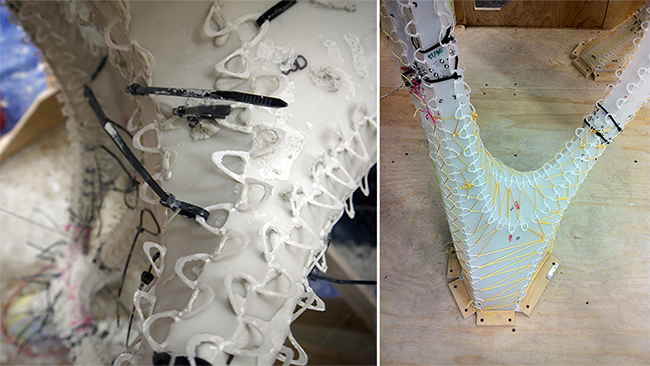

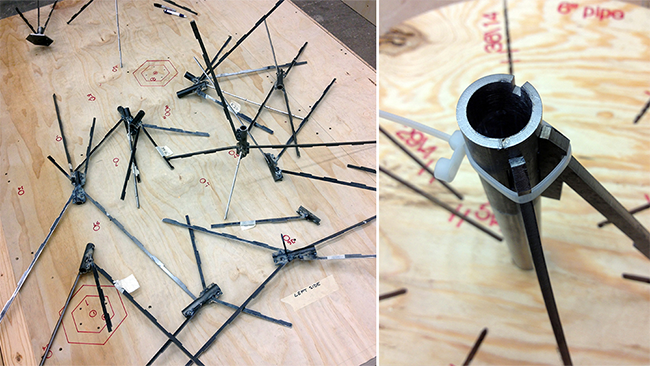

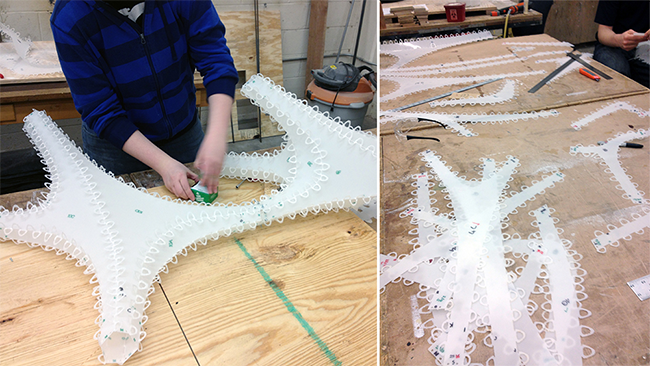

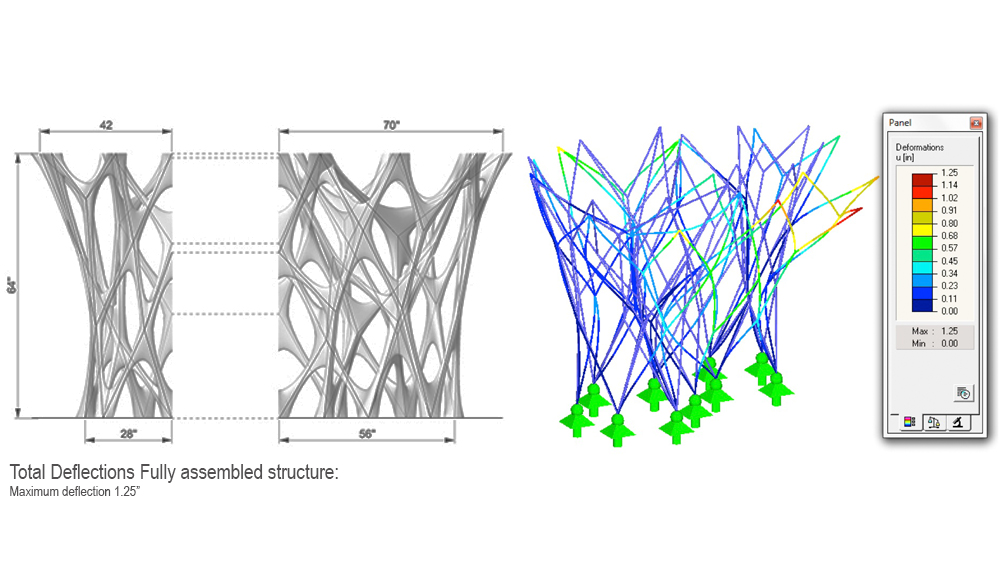

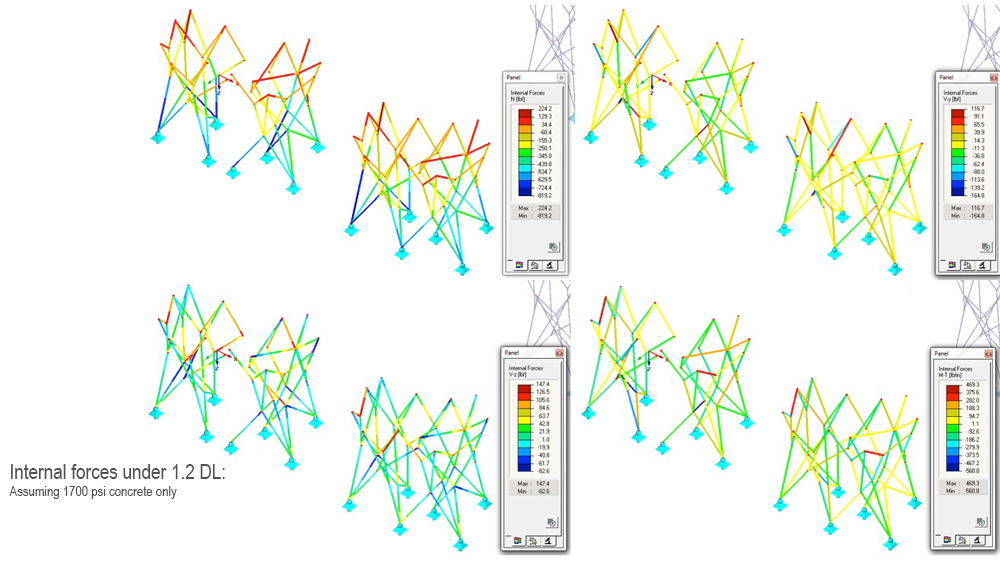

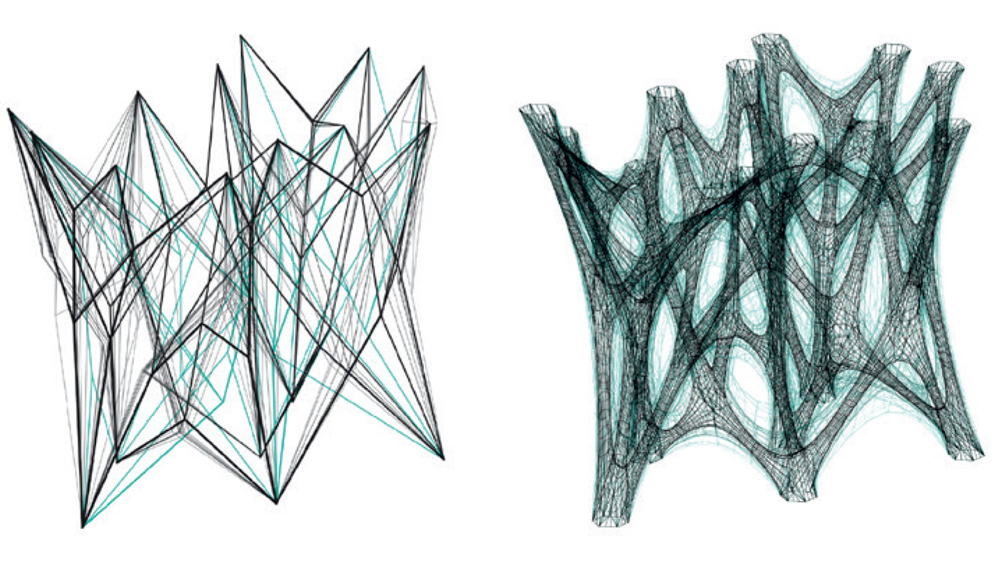

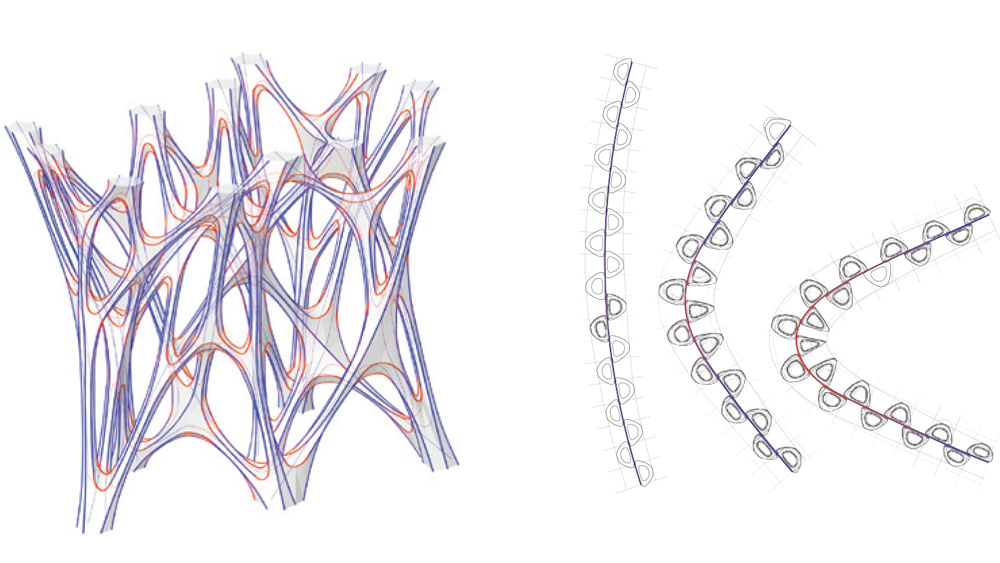

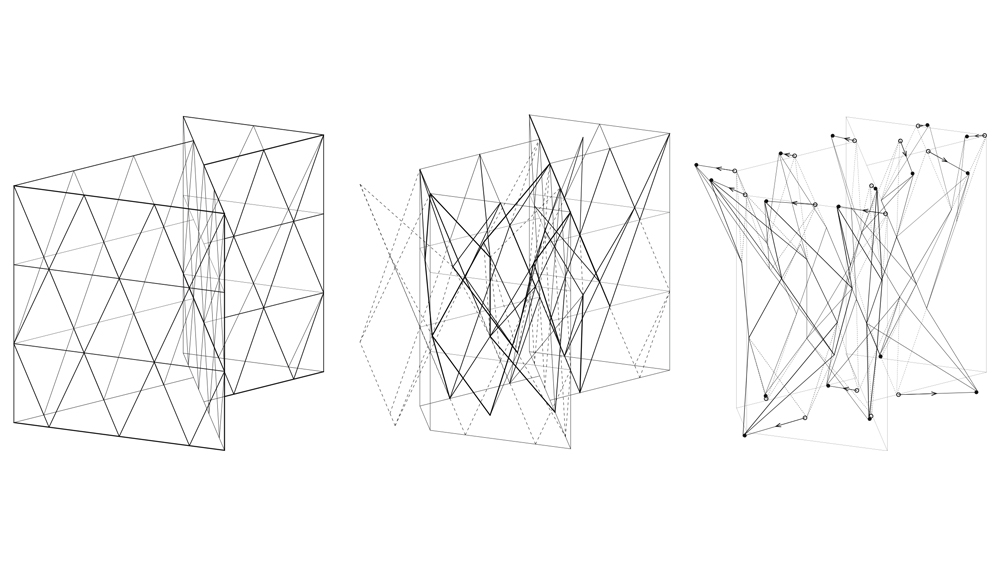

Cast Thicket continues a long but varied trajectory of research into the use of tensile and soft mold formwork. The use of polypropylene material formwork and custom fabricated nodes and struts for a tensile structural network, sets this work apart from other historical investigations. The ruled surface geometry of the hexagonal cross-section for each member of the larger piece provides an efficient and method for mold fabrication and structural stability. Seams for the hexagonal pieces are connected via an interlocking ‘zipper’ which facilitates an easy assembly process and further reinforces stiffness to the formwork once assembled. Individual members range in diameter from 3” to 6” and create a stable geometric configuration through triangulation.

The Cast Thicket research project is the result of a year-long competition and collaboration process between the YO-CY design office led by Ken Tracy and Christine Yogiaman, TEX-FAB, and the UT Arlington School of Architecture. This work provided one of the first opportunities to integrate multi-organizational research into the now permanent format of DARC. Working initially to resolve development and installation issues, students collaborated with outside consultants, fabricators and designers to help develop and realize the final piece.

Team Members

Craig Gilliam

Amy Jarvis

Jacob Narvaez

James Struthers

Lavender Tessmer

Ken Tracy

Jeff Whately

Christine Yogiaman

Industry Partners

Buro Happold Engineers

Crow Corporation

TEX-FAB

News & Publications

TxA Interactive 2013

Fabricate 2014

Related Projects

Multi-Nodal Columnar Branching

Cast Columnar Branching II

Cast Columnar Branching III